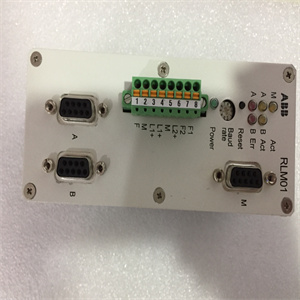

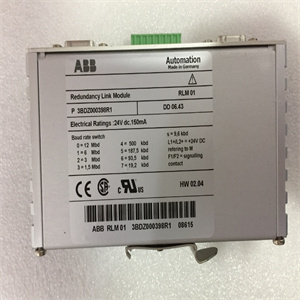

产品展示

联系我们

联系人:麦女士

手机:+86 15270269218

电话:

Q Q:3136378118

邮箱:stodcdcs@gmail.com

地址:江西省九江市瑞昌市东益路23号赛湖农商城401号

•根据负载电流选择横截面;

•验证电压降。

1.2电缆的安装和尺寸

电缆的选择

规范安装和计算的国际参考标准

住宅和工业建筑中电缆的载流量为

IEC 60364-5-52“建筑物电气装置-5-52部分选择和

电气设备的安装-布线系统”。

以下参数用于选择电缆类型:

•导电材料(铜或铝):选择取决于成本,

尺寸和重量要求,耐腐蚀环境

(化学试剂或氧化元素)。一般来说,承载能力

铜导体的承载能力大约比

相同横截面的铝导线。铝导体

同一横截面的电阻大约高出60%,并且

重量比铜导体低一半到三分之一。

•绝缘材料(无、PVC、XLPE-EPR):绝缘材料影响

正常和短路条件下的高温度,因此

导线横截面的利用[见1.4章“保护

防止短路“]。

•导线类型(裸导线、无护套单芯电缆、,

根据机械阻力、绝缘程度和安装难度(弯头、,

沿线接缝、障碍物……)安装方法要求。

表1显示了不同安装方法允许的导线类型。

1.2.1载流量和安装方法

导体

和电缆

安装方法

没有

固定件

剪裁的

直接的

管道

系统

电缆桥架

系统

(包括踢脚板

线槽,平齐地板

中继)

缆绳

管道

系统

电缆梯架,

电缆托架,电缆

括号

在…上

绝缘体

支持

金属丝

裸导体-----+-

绝缘导线b+++a+++-

谢尔特

电缆

(包括

装甲

和矿物

绝缘的

多核++++0+

单核0++++0+

+

–

0

被允许

不允许。

不适用,或在实践中通常不使用。

一

b

如果电缆槽系统的防护等级至少达到IP4X或

IPXXD,如果盖子只能通过工具或故意操作拆除。

用作保护导体或保护连接导体的绝缘导体可使用

适当的安装方法,无需铺设在导管、线槽或管道系统中。

272电气设备| ABB

1馈线保护

1.2电缆的安装和尺寸

表2:安装方法

对于工业装置,多芯电缆很少与横截面一起使用

大于95 mm2

.

安装方法

为了确定导体的载流能力,从而确定负载电流的正确横截面

必须确定更适合实际安装情况的安装

在上述参考标准中所述的标准中。

从表2和表3可以识别安装标识

编号、安装方法(A1、A2、B1、B2、C、D1、D2、E、F、G)和

定义导体理论载流容量的表格

以及考虑特定环境和

安装情况。

情况

安装方法

没有

固定件

剪裁的

直接的

管道

系统

电缆桥架

系统

(包括踢脚板

线槽,平齐地板

中继)

缆绳

管道

系统

电缆梯架,

电缆托架,电缆

括号

在…上

绝缘体

支持

金属丝

建筑物

空隙率

无障碍40 33 41、42 6、7、8、9、12 43、44 30、31、32、,

33, 34 - 0

无法访问40 0 41、42 0 43 0 0 0 0

电缆通道56 56 54、55 0 30、31、32、34--

埋在地下72、73 0 70、71-70、71 0--

-嵌入结构57、58 3 1、2、59、60 50、51、52、53 46、45 0--

表面安装-20、21、22、,

23, 33

4, 5 6, 7, 8, 9, 12 6, 7, 8, 9 30, 31, 32, 34 36 -

架空/空中自由-33 0 10、11 10、11 30、31、32、34 36 35

窗框16 0 16 0 0 0--

门楣15 0 15 0 0 0--

浸入式1+++-+0--

-

0

+

不允许。

不适用或在实践中通常不使用。

遵循制造商的说明

• choose the cross section according to the load current; • verify the voltage drop. 1.2 Installation and dimensioning of cables Selection of the cable The international reference Standard ruling the installation and calculation of the current carrying capacity of cables in residential and industrial buildings is IEC 60364-5-52 “Electrical installations of buildings – Part 5-52 Selection and Erection of Electrical Equipment- Wiring systems”. The following parameters are used to select the cable type: • conductive material (copper or aluminium): the choice depends on cost, dimension and weight requirements, resistance to corrosive environments (chemical reagents or oxidizing elements). In general, the carrying capacity of a copper conductor is about 30% greater than the carrying capacity of an aluminium conductor of the same cross section. An aluminium conductor of the same cross section has an electrical resistance about 60% higher and a weight half to one third lower than a copper conductor. • insulation material (none, PVC, XLPE-EPR): the insulation material affects the maximum temperature under normal and short-circuit conditions and therefore the exploitation of the conductor cross section [see Chapter 1.4 “Protection against short-circuit”]. • the type of conductor (bare conductor, single-core cable without sheath, single-core cable with sheath, multi-core cable) is selected according to mechanical resistance, degree of insulation and difficulty of installation (bends, joints along the route, barriers...) required by the method of installation. Table 1 shows the types of conductors permitted by the different methods of installation. 1.2.1 Current carrying capacity and methods of installation Conductors and cables Method of installation Without fixings Clipped direct Conduit systems Cable trunking systems (including skirting trunking, flush floor trunking) Cable ducting systems Cable ladder, cable tray, cable brackets On insulators Support wire Bare conductors - - - - - - + - Insulated conductors b - - + + a + - + - Shealted cables (including armoured and mineral insulated Multi-core + + + + + + 0 + Single-core 0 + + + + + 0 + + – 0 Permitted. Not permitted. Not applicable, or not normally used in practice. a b Insulated conductors are admitted if the cable trunking systems provide at least the degree of protection IP4X or IPXXD and if the cover can only be removed by means of a tool or a deliberate action. Insulated conductors which are used as protective conductors or protective bonding conductors may use any appropriate method of installation and need not be laid in conduits, trunking or ducting systems. 272 Electrical devices | ABB 1 Protection of feeders 1.2 Installation and dimensioning of cables Table 2: Method of installation For industrial installations, multi-core cables are rarely used with cross section greater than 95 mm2 . Methods of installation To define the current carrying capacity of the conductor and therefore to identify the correct cross section for the load current, the standardized method of installation that better suits the actual installation situation must be identified among those described in the mentioned reference Standard. From Tables 2 and 3 it is possible to identify the installation identification number, the method of installation (A1, A2, B1, B2, C, D1, D2, E, F, G) and the tables to define the theoretical current carrying capacity of the conductor and any correction factors required to allow for particular environmental and installation situations. Situations Method of installation Without fixings Clipped direct Conduit systems Cable trunking systems (including skirting trunking, flush floor trunking) Cable ducting systems Cable ladder, cable tray, cable brackets On insulators Support wire Building voids Accessible 40 33 41, 42 6, 7, 8, 9, 12 43, 44 30, 31, 32, 33, 34 - 0 Not accessible 40 0 41, 42 0 43 0 0 0 Cable channel 56 56 54, 55 0 30, 31, 32, 34 - - Buried in ground 72, 73 0 70, 71 - 70, 71 0 - - -Embedded in structure 57, 58 3 1, 2, 59, 60 50, 51, 52, 53 46, 45 0 - - Surface mounted - 20, 21, 22, 23, 33 4, 5 6, 7, 8, 9, 12 6, 7, 8, 9 30, 31, 32, 34 36 - Overhead/free in air - 33 0 10, 11 10, 11 30, 31, 32, 34 36 35 Window frames 16 0 16 0 0 0 - - Architrave 15 0 15 0 0 0 - - Immersed 1 + + + - + 0 - - - 0 + Not permitted. Not applicable or not normally used in practice. Follow manufacturer’s instructions

相关产品