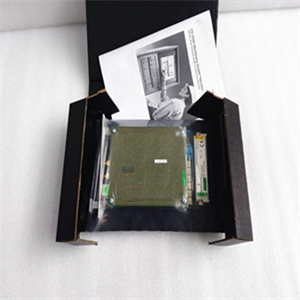

产品展示

联系我们

联系人:麦女士

手机:+86 15270269218

电话:

Q Q:3136378118

邮箱:stodcdcs@gmail.com

地址:江西省九江市瑞昌市东益路23号赛湖农商城401号

使用了无效的设置编号

更改指令中的设置编号

有效设置编号通常为1-3。更改指令并重新执行。

找不到梁

检查光束和/或改变起始点

如果找不到光束,就会出现这种情况。检查光束功能和/或改变

起点。

TCP估计函数失败

检查是否有足够的电线输出

如果在TCP估计过程中搜索失败,则会显示。

无法进行焊炬对准

检查横梁和/或电线杆是否伸出

如果在枪对准过程中搜索失败,则显示。

刀具测量功能失败

检查横梁和/或电线杆是否伸出

如果在测量TCP操作期间搜索失败,则会出现此消息。

警告!

面板笔直向下,刀具X轴将与横梁X平行。

请参阅手册,了解如何解决此问题。

如果系统检测到焊枪z轴平行,将出现此屏幕

带机器人安装法兰z轴。在这种情况下,TCP x轴方向可以

未计算。有两种可能的方法来解决这个问题。

1改变焊枪的角度。

2将BullsEye\u参数变量“ForceTcpQuat”设置为–1或1。这将

强制TCP的x轴与梁方向成90度角。设置为

1,x将沿与倾斜运动相反的方向移动。

BullsEye®7

BullsEye®安装

24 505 942-102

BullsEye®7

活动

505 942-102 25

5操作

5.1基本操作

当机器人调用CheckTCP例程时,BullsEye®将测量

TCP。安装了EasyArc的系统将具有菜单,允许操作员

轻松执行过程调用并处理来自系统保险箱的移动

BullsEye®装置的位置和接近点。在没有

EasyArc CheckTCP可以直接执行。在任何一种情况下,以下情况之一

将发生:

1如果TCP非常接近的TCP值,则不会进行更新,并且

机器人恢复生产。

2如果TCP在预定的允许误差范围内(X、Y和Z组合)

BullsEye®将自动更新的TCP设置,并允许

机器人返回生产。允许误差将设置为5mm,除非

可选设置参数MaxFrDay1设置为其他值。如果

程序在手动设定模式下运行,以下选项变为

在这种情况下可用:

如果已知工具弯曲,建议将焊炬向后弯曲至

原始位置。通过选择Day1Tcp,机器人将移动到参考位置

设置期间定义的指针。选择否允许机器人继续

更新TCP,就像在自动模式下一样。选择其中一个

Day1Tcp或Present TCP允许机器人移动到指针

各刀具处于激活状态。将出现以下屏幕:

程序正在等待数据!

Tcp与“当前”定义不匹配:

Present\u TCP-Day1\u TCP设置编号:1

x=2 Y=2 Z=1

Day1Tcp:设置时的tcp

存在:具有当前值的tcp

是否在更新TCP之前移动到指针?

选择要在指针处使用的tcp或

否以继续tcp更新。

Day1Tcp当前编号

程序正在等待数据!

枪现在应该在指针上。

如果不是,则可能需要手动

向后弯曲至指针。

选择要在指针处使用的tcp或继续。

1天CP/当前编号

Invalid setup number is used Change setup number in instruction Valid setup numbers are normally 1-3. Change instruction and re-execute. The beam could not be found Check beam and/or change startpoint This comes up if the beam could not be found. Check beam function and/or change the start point. The TCP estimate function failed Check if enough wire is fed out Comes up if a search failed during TCP estimation. Torch alignment could not be done Check beam and/or wire stick-out Comes up if a search failed during gun alignment. Tool measurement function failed Check beam and/or wire stick-out Comes up if a search failed during measure TCP operation. WARNING ! Face plate pointing straight down, tool X axis will parallel with beam X. Check with the manual on how to correct this problem. This screen will appear if the system detects that the welding gun z axis is parallel with the robot mounting flange z axis. In this situation the TCP x axis direction can not calculated. There are two possible ways to cope with this problem. 1 Change the angle of the welding gun. 2 Set BullsEye_Param variable “ForceTcpQuat” to either –1 or 1. This will force the x axis of the TCP to be 90 degrees from the beam direction. Set to 1, x will go in the direction opposite the tilt motion. BullsEye® 7 BullsEye® Installation 24 505 942-102 BullsEye® 7 Operation 505 942-102 25 5 Operation 5.1 Basic Operation When the CheckTCP routine is called by the robot, the BullsEye® will measure the TCP. A system with EasyArc installed will have menus which allow the operator to easily execute the procedure call and handle movements from the system’s safe position and the approach point to the BullsEye® unit. In a system without EasyArc CheckTCP can be executed directly. In either event, one of the following will happen: 1 If the TCP is very close to the Day-1 TCP values, no update is made, and the robot returns to production. 2 If the TCP is within a predetermined allowed error (X,Y, & Z combined) of its Day-1 set up TCP, BullsEye® will automatically update it and allow the robot to return to production. The allowed error will be set at 5mm, unless the optional set up parameter MaxFrDay1 is set to some other value. If the program running in manual teach mode the following options become available in this situation: If the tool is known to be bent, it is recommended that the torch be bent back to the original position. By selecting Day1Tcp the robot will move to the reference pointer defined during the set up. Selecting NO allows the robot to continue with updating the TCP, much as it would do in automatic mode. Selecting either Day1Tcp or Present TCP allows the robot to move to the pointer with that respective tool active. The following screen will appear: Program Waiting for Data! Tcp does not match "Present" definition: Present_TCP - Day1_TCP SetupNo: 1 x=2 Y=2 Z=1 Day1Tcp: tcp when setup was made Present: tcp with present values Move to pointer before updating TCP? Select which tcp to use at pointer or NO to continue with tcp update. Day1Tcp Present NO Program Waiting for Data! The gun should now be on the pointer. If not, it may need to be manually bent back to the pointer. Select which tcp to use at pointer or PROCEED to continue. Day1Tcp/Present NO

相关产品