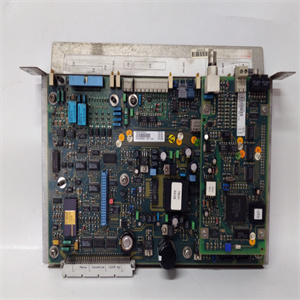

产品展示

联系我们

联系人:麦女士

手机:+86 15270269218

电话:

Q Q:3136378118

邮箱:stodcdcs@gmail.com

地址:江西省九江市瑞昌市东益路23号赛湖农商城401号

o围绕TCP旋转所有机器人轴将移动

相应地保持TCP恒定(见图4和图5)。如果火炬

当程序再次运行时,机器人重复其相同的动作,但

TCP可能不再遵循相同的编程路径,原因是

未对准。您现在有两个选择:

1实际移动焊炬使其重新对齐(这项任务可能很困难

如果不是不可能的话)

2通过将TCP重新定义为新的

使用BullsEye®进行火炬定位。BullsEye®系统更新

当前TCP定义,火炬将像以前一样围绕TCP旋转

因为机器人手臂已经调整了路径以补偿火炬

未对准。

图4机械臂和火炬在TCP正确的情况下移动

图5机械臂遵循相同的路径,但火炬路径已更改

BullsEye®7

产品描述

505 942-102 11

编程点后,机器人会记住刀具中心点

位置,而不是机器人关节的角度。当机器人重播

编程路径,它计算关节角度,以恢复TCP

到路径初编程时的位置。只要机器人

控制器始终被告知刀具中心点的位置,它将始终保持

正确调整路径。

3.3 BullsEye®优势

版本7.0 BullsEye®的新增功能:

1操作与先前版本6.3 BullsEye®类似。

2示教器文本现在位于单独的系统模块中。此更改

允许其他人将文本翻译成其他语言

ABB部门。

3 7.0版现在与中提供的运动监控兼容

BaseWare 3.2版本。20及以上。

BullsEye®7

产品描述

12 505 942-102

BullsEye®7

BullsEye®安装

505 942-102 13

4 BullsEye®安装

4.1机械安装

BullsEye®应栓接在地板上(独立式)或固定在某个位置

机器人可以到达的地方以及不妨碍人员工作的地方

机器人周围。

图6基准坐标

安装并执行软件时(见第4.3节),机器人将旋转

焊丝周围正负30度或45度(见图7)。四十五

(45)度将达到佳精度。选择用于安装的位置

BullsEye®不仅必须允许机器人够到它,而且这个位置还必须

允许机器人在BullsEye®工作中轻松绕过其TCP

包络,而不会导致机器人超出其关节限制。

图7 45°的对齐角度效果佳

BullsEye®7

BullsEye®安装

14 505 942-102

好的安装程序是将独立式BullsEye®放置在

所需位置,无需固定。执行软件安装

并执行第4.3节所述的BullsEye®设置程序。如果

robot能够完成完整的TCP更新过程,并成功完成

在满足所有其他位置要求的情况下进行快速检查,然后用螺栓固定

牢固就位。

侧装式牛眼座的安装方式也必须允许无限制

机器人访问。

4.2电气安装

BullsEye®在工厂预接线,便于组装。连接电缆

从BullsEye®装置上的插座提供至控制器机柜。

使用下图进行安装。

图8显示了机器人控制器机柜中导线的端点

输入/输出模块和24VDC接线板处。

图8 BullsEye上公插座的接线图,550 880-001。

连接BullsEye,550 880-001。

1白色电缆(2014045)导线连接至24 VDC

2黑色电缆(2014045)导线(传感器1的信号)连接至输入/输出

3绿色电缆(2014045)导线连接至0 VDC

用三根电缆连接BullsEye,501 527-880。

1蓝色电缆线连接至24V DC,端子上的端子4

TC 96中的块和Binzel BRS-LC中的1块。

2棕色导线连接至TC接线板上的0V端子8

宾泽尔BRS-LC中的96和3。

3连接至传感器输入的黑色导线,接线板上的连接16

Binzel BRS-LC中的TC 96和10。

o revolve around the TCP all robot axes will move accordingly to keep the TCP constant (See Figure 4 and Figure 5). If the torch is bumped and the program is run again, the robot repeats its same movements but it is possible that the TCP will no longer follow the same programmed path due to misalignment. You now have two choices: 1 Physically move the torch back into alignment (a task that could be difficult if not impossible) 2 Adjust for the misalignment automatically by redefining the TCP to the new torch position using the BullsEye®. After the BullsEye® system updates the current TCP definition, the torch will rotate around the TCP as before because the robot arm has adjusted its path to compensate for the torch misalignment. Figure 4 Robot Arm and Torch Movement With Correct TCP Figure 5 Robot Arm Follows Same Path But Torch Path Has Changed BullsEye® 7 Product Description 505 942-102 11 Once a point has been programmed, the robot remembers the tool center point location, not what the angles of the robot joints are. When the robot replays the programmed path, it calculates what the joint angles should be to get the TCP back to where it was when the path was programmed initially. As long as the robot controller is kept informed about where the tool center point is, it will always keep the paths properly adjusted. 3.3 BullsEye® Advantages New for version 7.0 BullsEye®: 1 Operation remains similar to predecessor, version 6.3 BullsEye®. 2 Teach pendant text now resides in a separate system module. This change allows provision for the text to be translated into other languages by other ABB divisions. 3 Version 7.0 is now compatible with Motion Supervision available in BaseWare 3.2 rev.20 and higher. BullsEye® 7 Product Description 12 505 942-102 BullsEye® 7 BullsEye® Installation 505 942-102 13 4 BullsEye® Installation 4.1 Mechanical Installation The BullsEye® should be either bolted to the floor (freestanding) or in a position where the robot can reach it and where it is not in the way of personnel working around the robot. Figure 6 Base Coordinates When the software is installed and executed (see Section 4.3), the robot will swivel around the weld wire plus and minus 30 or 45 degrees (See Figure 7). Forty-five (45) degrees will achieve the best accuracy. The position chosen for mounting the BullsEye® must not only allow the robot to reach it, but this position must also allow the robot to easily maneuver around its TCP within the BullsEye® work envelope without causing the robot to exceed its joint limits. Figure 7 Alignment Angle Of 45° Works Best BullsEye® 7 BullsEye® Installation 14 505 942-102 The best procedure for installation is to place the Freestanding BullsEye® in a desired position without securing it permanently. Perform the software installation and execute the BullsEye® setup procedures as described in section 4.3. If the robot is able to complete the full TCP update process and successfully completes a Quick Check routine while meeting all other location requirements, then bolt it solidly in position. Side Mount BullsEye’s must also be mounted in a manner to allow unrestricted robot access. 4.2 Electrical Installation The BullsEye® is pre-wired at the factory for easy assembly. Connect the cable provided from the receptacle on the BullsEye® unit to the controller cabinet. Use the following diagram for installation. Figure 8 shows the termination points for the wires in the robot controller cabinet at the I/O Module and 24VDC terminal blocks. Figure 8 Wiring Diagram for Male Receptacle on BullsEye, 550 880-001. Connecting BullsEye, 550 880-001. 1 The white cable (2014045) wire goes to 24 VDC 2 The black cable (2014045) wire (signal to sensor 1) goes to I/O 3 The green cable (2014045) wire goes to 0 VDC Connecting BullsEye, 501 527-880, with three cables. 1 The blue cable wire is connected to 24V DC, terminal 4 on the terminal block in TC 96 and 1 in Binzel BRS-LC. 2 The brown wire is connected to 0V, terminal 8 on the terminal block in TC 96 and 3 in Binzel BRS-LC. 3 The black wire to the sensor input, connection 16 on the terminal block in TC 96 and 10 in Binzel BRS-LC.

相关产品